Material flow system DPS

... Industry 4.0 put into practice

DPS is a flexible, integrating and cost-effective system of autonomous functional blocks.

The objective is to deliver of our customers an innovative, customized cost-optimized solution for the areas

- material flow control

- warehouse management

- picking

which can be integrated with minimal effect on the production or logistics process even during operation.

The DPS System is not a monolithic application, but an open and integrating framework. Specific functional areas or intralogistic mechanics are mapped on the basis of a standardized communication and runtime environment with reusable modules.

These days, there are hundrets of modules for all conceivable tasks available E.g for different conveyors, pushing mechanics, barcode scan, label printing etc.

Integration

It is the objective to support and integrate different mechanics, from diffenet vendors. Without generating a tight vendor lock-in.

Modernizations of existing hardware components can be done inexpensive and often during operation, or with little downtime.

We integrate goods-to-man and man-to-goods picking systems, eg. by means of a pick by light installation.

Flexibility

F&J DPS modules, as well as manufacturer-integration modules can be replaced or supplemented by existing components or functionality of third parties if necessary. Only the core functionality of the communication and runtime environment is fixed.

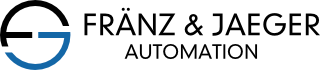

DPS decentral programmable controller

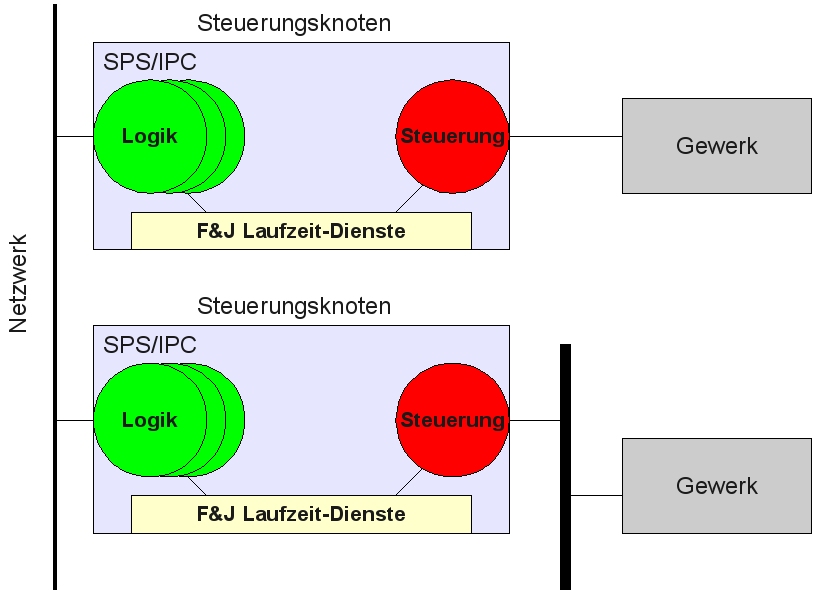

Fränz & Jaeger uses the technology of decentralized, distributed and semi-autonomous control and application functions by software agents (software services). This corresponds to the current SOA technology (Service Oriented Architecture) within the IT.

Even a master computer is mapped via the software agent technology as a "logical" topology and is independent of its physical implementation (Host/IPC/PLC).

This allows running functions of material flow control and picking on a central computer, as well as autonomously on remote nodes.

Further, the topologies of the PLC, as well as that of the IPC's, or the PAC, is supported in parallel and also mixed in practice. We are using the CoDeSys IEC 61131 environments, STEP7, INFOTEAM IEC61131 or appropriate high-level languages C, Python, Java for business functions.

Optimal concept

The F&J concept decouples the application and control logic as well as business and process data from the actual process flow.

The business and process data of the material or assembly flow is transported in a kind of "docket" (Business data object) from control point to control point and from logic agent to logic agent in terms of the sequential control system. The electronic docket is evaluated and updated at any control point.

This concept makes it possible to map very complex processes and we can expand it while in operation.

It is also possible to integrate vendor specific "ready to use" funktionblocks to control agents, the material flow control remains independent.