Sorter systems

... sorting at a good price

The clients' situation

In almost any logistical use case goods must be sorted, here e.g. packages on truck tours. Although standard sorters provide a solution, they have benefits on top of what is most times needed and at a price that does not justify their operation. Alternatively, the only possibility was manual sorting.

Our solution

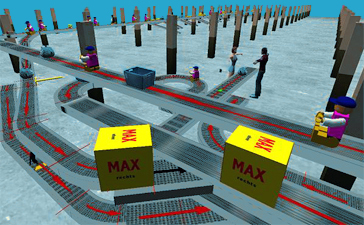

We provide individually suited sorters laid out for an average capacity up to 3000 units per hour and a maximum weight of 40 kg. They can be composed using conventional conveyor technology and are priced accordingly. Fränz & Jaeger designs the best sorter system for your needs using approved components.

Control technology

Concerning the realization of control technology systems we use the latest technologies. Camera-based omnidirectional scanning and decentralized controlers based on WAGO IPC (Linux based with CeDeSys SPS component) to ensure our customers an optimal cost-effective solution.

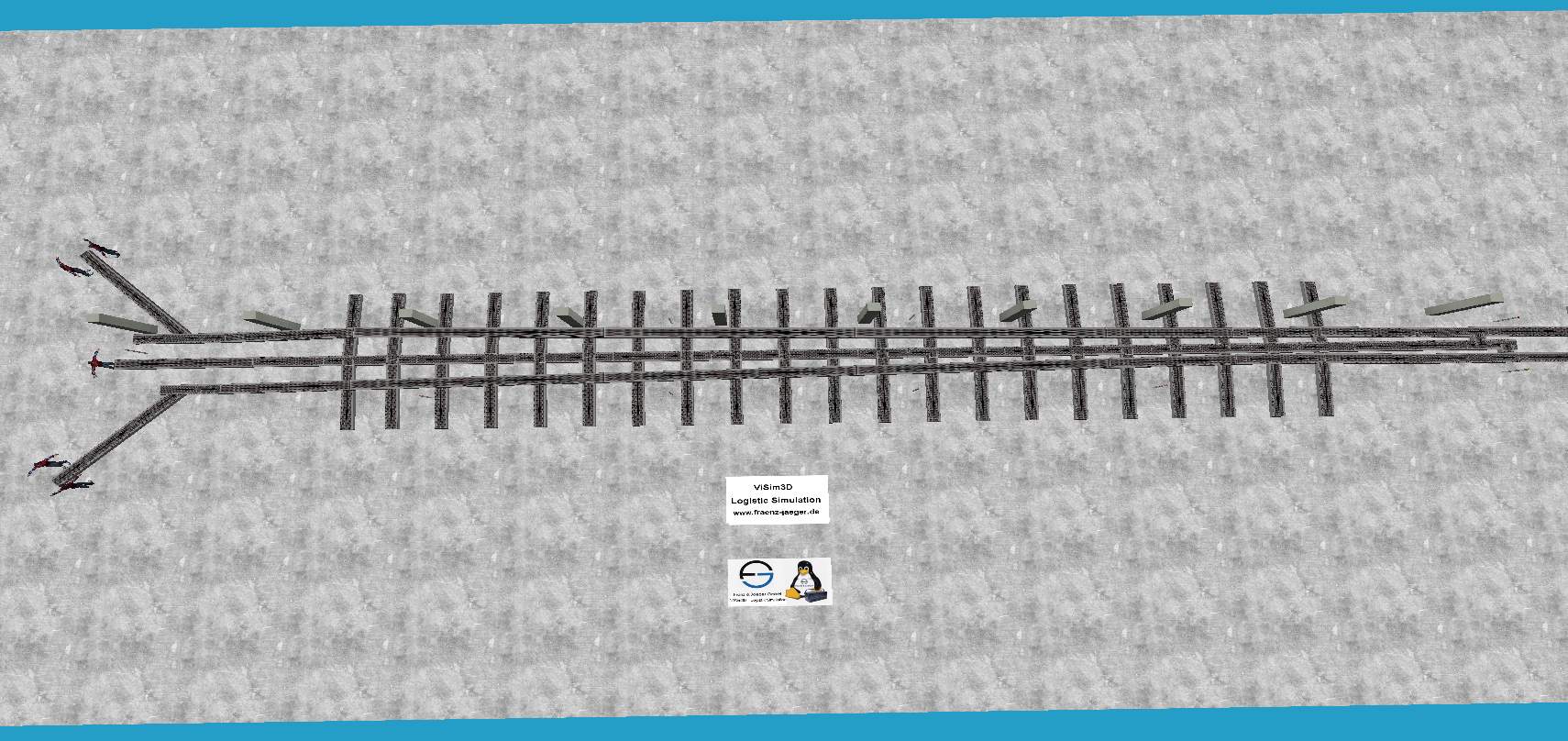

Optimization

Our special 3D simulation environment allows a faithful planning and simulation of the system in question with optimization of the controler in real time. The result is an efficient, cost-effective implementation without loss of production time.

Operational safety

Even during operation, the system is continuously monitored by our process control system ZMS. It can be maintenanced locally or remotely at any time with new software versions over the network.

Conclusion

Fränz & Jaeger designs the optimal sorting system for customers needs composed of approved components:

- Identification and mapping - the applicated barcodes on the goods to be sorted are optically recorded from multiple sides by a camera system. For unambiguous identified units the sorter exit can be assigned fully automatically. Otherwise the recorded images are forwarded to a manual or teleworking editing place where they are identified by human workers.

- Weighing - Optionally the units can be weighted by a continuous electronic balance.

- Printing of result label - Finally an unambiguous result label is printed on lth fly. For this purpose we use printers with blowing air technology because they guarantee stable application even on rough surfaces.

- Sorter routing and ejection - The last step is to convey the unit to the actual sorter element which realizes the ejection (using pop-up or belt conveyer). The number of exits is only limited by the length of the facility.

Conveyer technique is realized in cooperation with notable vendors. The technique is operated and controled by our approved DPS-system (Decentral Programmable Controler). The successor of classic PLC (SPS in German) and ready for industry 4.0.